STICK PACK MACHINES

- Home

- Lorum Ipum

- Page Title

STP-600 | STP-900 | STP-1200

Multi-Track Stick Pack Machines

Innomation’s STP Series are vertical, intermittent-

motion, fully servo-driven packaging machines that blend European engineering quality with Indian manufacturing agility. Built for industries where reliability, regulatory compliance, and cost-efficiency are paramount, these machines support a wide range of package formats and dosing systems.

The STP range is available in configurations tailored to Pharmaceutical, Nutraceutical, Food & Beverage, and Consumer Goods applications.

Dosing Systems – Powders & Granules

Powders

For free and non-free flowing products

Our in-house designed and precision-machined auger filler features a temperature-controlled casing, ensuring jam-free, high-accuracy filling—even with challenging powders like cocoa, milk powder, powdered sugar, and ground spices.

Granules

For Free-Flowing Products

Our Basculation dosing systems offer outstanding filling accuracy, even with irregular granules of varying bulk densities. They are crafted for easy cleaning and quick changeovers, ensuring seamless operation with minimal downtime.

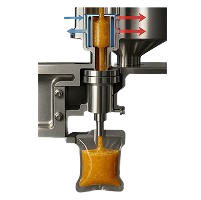

Liquids & Pastes

For fluid and thick products

Innomation offers both piston and ultrasonic fillers for a wide range of liquids and pastes.

Temperature-controlled filling ensures consistent weight accuracy and jam-free operation.

Discrete Products

Tablets, capsules, candies, and other discrete products

Tablets, capsules, candies, and other discrete products can be efficiently counted and dispensed from bulk into individual stick packs. Integrated visual inspection and rejection systems ensure that only quality-verified products reach your customers.

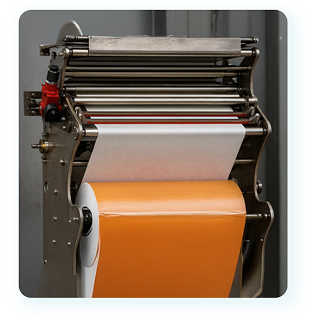

Key Features - Web handling

Feature:

Continuous Unwinder

Benefit:

Enables jerk-free film unwinding, helping reduce laminate costs while improving machine throughput.

Feature:

Servo Controlled Web Guiding

Benefit:

Offers up to 100 mm of high speed correction, ensuring precise laminate centering

Feature:

Ergonomically designed & Automated splice Table

Benefit:

Automatic clamping and guided cutting significantly reduce splicing time, errors, and material wastage.

Key Features - Sealing

Feature:

Fully Servo Controlled Sealing

Benefit:

Enables independent electronic adjustment of sealing time, temperature, and pressure for optimal seal strength and consistency.

Feature:

PVD Coated Sealing Jaws

Benefit:

Enhances heat transfer and surface temperature uniformity while reducing stickiness and material buildup

Feature:

Cascading Temperature control

Benefit:

Extends cartridge heater life and provides redundancy in temperature monitoring – reducing maintenance costs and improving sealing reliability.

Key Features - Performance & Compliance

Feature:

Machined Collars

Benefit:

Machined, retractable collars enable quick and reliable changeovers increasing machine availability

Feature:

Fully enclosed Transparent polycarbonate Guards

Benefit:

ensuring operator safety

Feature:

Optimized for Speed – 90 CPM

Benefit:

Increase your productivity while simultaneously saving on space, energy, and maintenance costs.

Specification

| STM-600 | STM-900 | STM-1200 | |

|---|---|---|---|

| POUCH TYPES | Fin Seal | 3 Side Seal | Die Cut | Contour Seal | Twin Pack | ||

| PRODUCT TYPES | Powders | Granules | Liquids | Pastes | Discrete products | ||

| POUCH WIDTH (MIN / MAX) | 17mm / 75 mm | ||

| POUCH LENGTH (MIN / MAX) | 50 mm / 120 mm | ||

| SPEED (CPM) * | 120 | 100 | 90 |

| THROUGHPUT (PPM) * | 1440 | 1500 | 1350 |

| NO. OF TRACKS | 15 – Max | ||

| REEL DIAMETER (MM) | 450 Max | ||

| REED WIDTH (MM) (MIN/MAX) | 450 - 600 | 600 - 900 | 900 – 1200 |

| COMPRESSED AIR | 12 CFM, 6 Bar | 15 CFM, 6 Bar | 18 CFM, 6 Bar |

| DEMANDED LOAD (3 PHASE 415 VAC, 50 HZ) | 15 KVA | 18.5 KVA | 22.5 KVA |

| FOOTPRINT (W X D X H) (MM) | 2150 x 3400 x 3500 | 2450 x 3400 x 3500 | 2750 x 3400 x 3500 |

| TYPES OF LAMINATE | Plastic Laminates: PET / PE, PET / ALU / PE, PET | MET-

PET / PE, BOPP / PE, PET / CPP Paper Based Laminates: Paper / PE, Paper / ALU / PE Coextruded Films: Nylon / PE, or EVOH based multilayers | ||

| *, Mechanical speed. Actual machine output is subject to product and packaging properties. (S= Standard, O= Optional, -- = Not Applicable) | |||

Options

| Title | Types | STM-600 | STM-900 | STM-1200 |

|---|---|---|---|---|

| Printing | Ink Jet Printing | S | S | S |

| Thermal Transfer Printing | O | O | O | |

| Laser Printer | O | O | O | |

| Hot Stamp | O | O | -- | |

| Print Verification | OCR | O | O | O |

| OCV | O | O | O | |

| Bar Code Reader | O | O | O | |

| QR Code Reader | O | O | O | |

| Track & Trace | O | O | O | |

| Slitting | Crush Type | S | S | S |

| Shear Type | O | O | O | |

| Ultrasonic Slitter | O | O | -- | |

| Laser Slitter | O | O | -- | |

| Notch Options | Rounded | O | O | O |

| V Cut | O | O | O | |

| Straight Cut | O | O | O | |

| Micro Perforation | O | O | O | |

| Sealing | ||||

| Contour | O | O | O | |

| Knurled | S | S | S | |

| Embossing | O | O | O | |

| Cutting | ||||

| Perforation | S | S | S | |

| String Sachet | S | S | S | |

| Die Cut | O | O | O | |

| Serrated Cut | S | S | S | |

| Straight Cut | O | O | O | |

| Inspection | ||||

| Thermal Camera | O | O | O | |

| Vision Inspection system | O | O | O | |

| Check Weighing | O | O | O | |

| Metal Detection | O | O | O | |

| CIP Enabled | O | O | O | |

| LARGE DIA REEL | 800 mm Dia (6” Core) | -- | O | O |

| TROUBLESHOOTING | S | S | S | |

| DUST SUCTION FROM DOSING | S | S | S | |

| INERT GAS FLUSHING | O | O | O | |

| FORMAT CHANGE TROLLEY | O | O | O | |

| EDGE TRIMMING AND RECOVERY | O | O | O | |

| EDGE TRIMMING AND RECOVERY | O | O | O | |

| BOTTOM-UP NOZZLE FILLING | O | O | O | |

| FILM STERILIZATION | O | O | O |

Pre Feeding Units

Innomation offers a comprehensive range of pre-feeding units designed to extend the intervals between manual product loading and to serve as buffers between upstream processing and downstream packaging operations. Our solutions include:

Bucket Eevator

Pneumatic Conveyor

Tube Chain Conveyor

Liquid Pumping

Inclined Screw Conveyors

Pneumatic Conveyors

Tube-chain conveyors

Z-Bucket

Elevators

Liquid storage & pumping station

Value Proposition

Innomation is an ISO 9001:2015 certified, full-service equipment lifecycle partner. Since our founding in 2005, we have successfully addressed some of the most demanding automation challenges across a wide range of industries—including pharmaceuticals, food & beverage, consumer goods, automotive, and aerospace. Renowned for our problem-solving expertise, we deliver high-performance solutions that meet the highest standards of safety, reliability, and efficiency.

Tailor-Made Solutions

Easy to operate and maintain

World class equipment

Flexible, Reliable, and lasts forever.

Focus on Usability

To meet you unique needs

Made in India

Available at short notice & economical

IIoT-Enabled Support

Quick breakdown resolution

Real Time Insights

KPI Insights available anytime, anywhere

Customization & Support

Innomation’s Design Room is staffed by a team of seasoned specialists, each bringing decades of experience in solving complex automation challenges. Equipped with state-of-the-art hardware and advanced software tools, the team excels in conceptualization, digital simulation, finite element analysis, and design validation.

Innomation’s Extensive Service Network ensures rapid, reliable support across India. Our systems are equipped for real-time remote troubleshooting, allowing instant diagnostics and resolution. When on-site support is required, our trained technicians can reach any location in India within 24 hours.

End-To-End In-House Manufacturing

Our precision machining facility is equipped with advanced CNC milling, CNC turning, EDM, and 5-axis machining centres. Backed by robust, aerospace-compliant quality systems, it supports the production of high-precision components for both our own packaging equipment and critical aerospace applications.

Innomation’s Fabrication facilities Include Cobot-assisted welding, laser cutting, CNC bending, and vapor blasting equipment.

This modern setup enables us to fabricate structural frames, enclosures, and custom parts entirely in-house—ensuring faster turnaround, and stringent quality compliance.