Vacuum Cooling - Baked Goods

- Home

- Automation Solutions

- Food & Beverages Process Automation

GAME-CHANGING ADVANTAGES

Vacuum cooling is a revolutionary process of cooling baked goods with many inherent advantages such as

Ultra-Fast Cooling

Reduce cooling time after baking from hours to minutes

Space Saving

Save up to 70% floor space

Energy Saving

Save up to 30% baking energy

Greater Product Volume

Increase product volume by up to 20% due to expansion during vacuum cycle

Longer Shelf Life

Rapid cooling reduces probability of bacteria growth and increases shelf life

Independent of Ambient

Consistent productivity and quality year-round that allows streamlining of supply and demand

Versatility

Vacuum cooling technology is highly versatile and considerably enhances the productivity and quality of almost all baked products. Further, vacuum cooling offers unique advantages based on the ingredients and the baking process.

French Bread

Can be quickly cooled with cycle times as low as 1.5 minutes while improving crispiness of the crust, freshness of the crumb, overall volume, and shelf life.

Cakes & Muffins

Can be cooled reasonably quickly with improved product texture, bite, and shelf life.

Toast or Rusk

Vacuum cooling increases the product volume and reduces the baking & toasting time by up to 30%, while maintaining productivity & quality year-round.

Equipment Range

Innomation offers a wide range of vacuum cooling systems that are custom built to meet the unique needs of our clients and their products. Generally, our equipment can be divided into semi-automatic and fully automatic range of vacuum cooling systems.

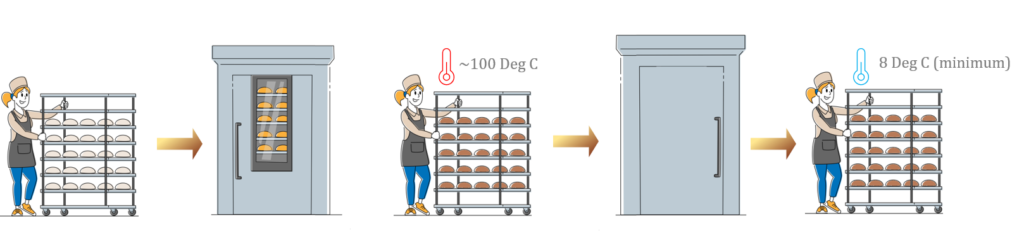

InnoVAC COSMO

Proofed dough in a trolley

Rotary rack oven

Freshly baked goods in a trolley

Vacuum chamber – Trolley model

Cooled goods – Ready for further process

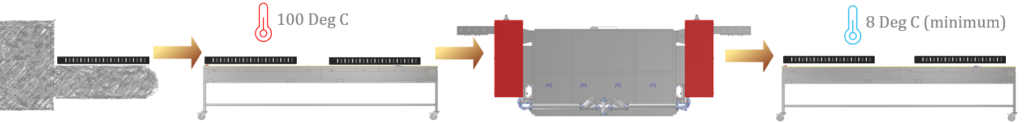

InnoVAC INDIE

Tunnel Oven

Freshly baked goods are conveyed to vacuum chambers

Fully automated vacuum chambers

Perfectly cooled goods conveyed downstream

InnoVAC COSMO

Typical Throughput : 20 Tons / Day

Suitable for

1. Artisan Bakeries.

2.Commercial Establishments.

3.Pilot facilities at industrial bakeries.

SALIENT FEATURES

Flexible

Multiple recipes can be configured for various products.

Safe

Food-grade direct contact materials. In-built emergency systems for man, machine & product safety.

Compact

Low maintenance and occupies less space.

Energy Efficient

Optional waste heat recovery for enhanced payback.

Easy to Use

User friendly human-machine interface. Easy to handle, simple to operate.

Easy to Maintain

State of the art mechatronics used for seamless operations of the machine. Remote troubleshooting assist system.

InnoVAC INDIE

Typical Throughput : 100 Tons / Day

Custom built to suit the world’s largest industrial bakeries

SALIENT FEATURES

Safety

In-Built multiple redundancy electro-mechanical safety features.

Construction

Modular construction of chambers which can be stacked vertically or horizontally to achieve higher throughputs. Much lighter in weight compared to conventional Monoblock system.

Hygiene & Quality

Zero manual handling in turn results in better hygiene, product quality & consistency.

Machine Vision System

Integrated machine vision systems and non contact temperature measurements continuously monitoring and adjusting system parameters for optimal quality.

Easy To Maintain

State-of-the-art mechatronics used for seamless operations of machine. Built-in troubleshooting assistance system.

Integration

Seamlessly integrates upstream (Baking oven) & downstream (Slicing/Toasting/Packing) processes.