Counting & Batching

- Home

- Automation Solutions

- Packaging Automation

A variety of discrete products such as candies, tablets, soup cubes, etc., are packaged into jars/cartons or containers which are subjected to stringent government regulations regarding weight and count accuracy. Innomation has developed, patented, and deployed counting and batching systems with accuracies well beyond the 3 sigma range enabling our clients to not only meet and exceed statutory requirements but also minimize consumer complaints and maximize product savings by eliminating excess count/SKU.

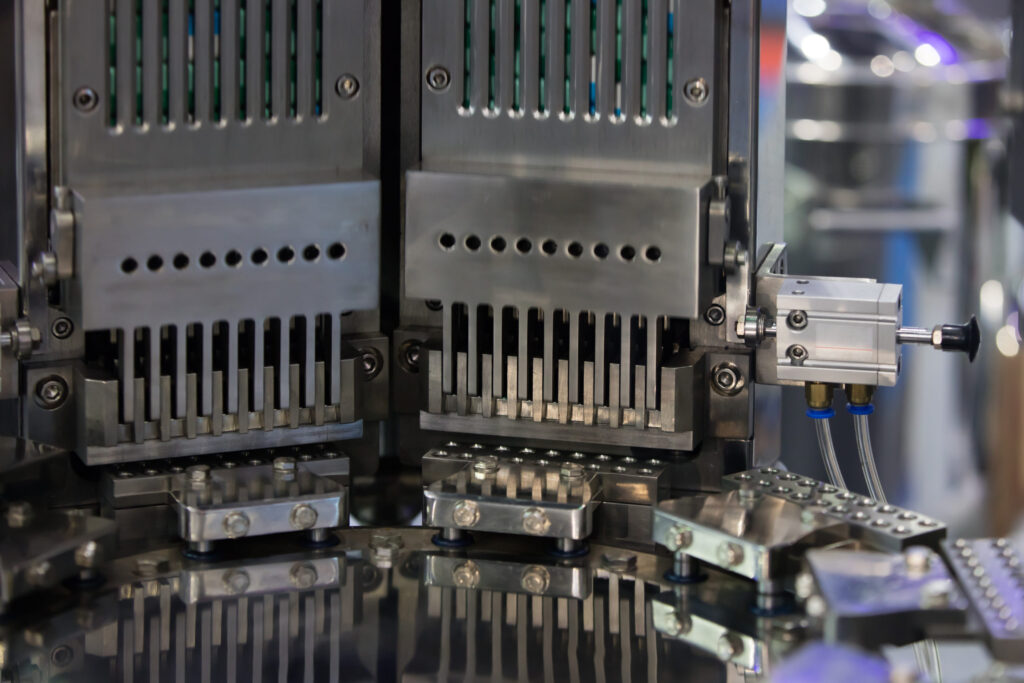

The candies or tablets are collected first in a hopper which dispenses them into a vibratory unscrambling system. Multiple configurations of vibratory unscrambles can be integrated into this system to handle almost any variety of products. The vibratory unscrambles feed the product in multiple rows to a specialized counting and batching assembly which then collects a specific number of products and dispenses them into jars/cartons/pouches as per the client’s packaging configuration. Moreover, automating jar handling, case erection, and even pouch form fill and seal machines can be directly integrated into the counting and batching system to maximize productivity.

SALIENT FEATURES

Accuracy

Assured 3 sigma or higher count accuracy

Integrated Weighing System

Integrated check weight system for count and weight confirmation for every SKU

Eliminate Product Damage

Optional zero back pressure hopper to eliminate product damage due to excessive buffering maximizing hopper capacity

Hygiene

Customizable to meet hygiene standards for both food and pharmaceutical applications

Quick Changeover

Modular vibratory unscrambling trays enables quick changeover for multiple products

IoT

IoT enabled sensors and continuous health monitoring of sensors and batching gate servo motors ensuring zero failures