Digital Manufacturing Solutions

Founded in year 2005

Lean & Agile Organization

Marquee Global Clientele

About – Innomation

Accelerating global prosperity through innovative & high impact manufacturing technologies

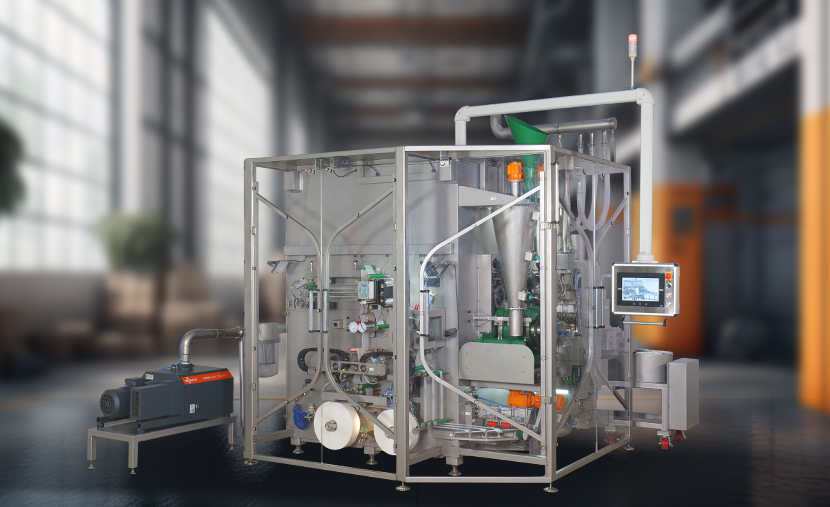

Industrial Automation Solutions

Processing, Packaging, Conveying, and custom automation solutions for Pharmaceutical & FMCG requirements.

Precision Manufacturing Services

CNC Machining, Fabrication, and Clean room assembly services for mission critical components.

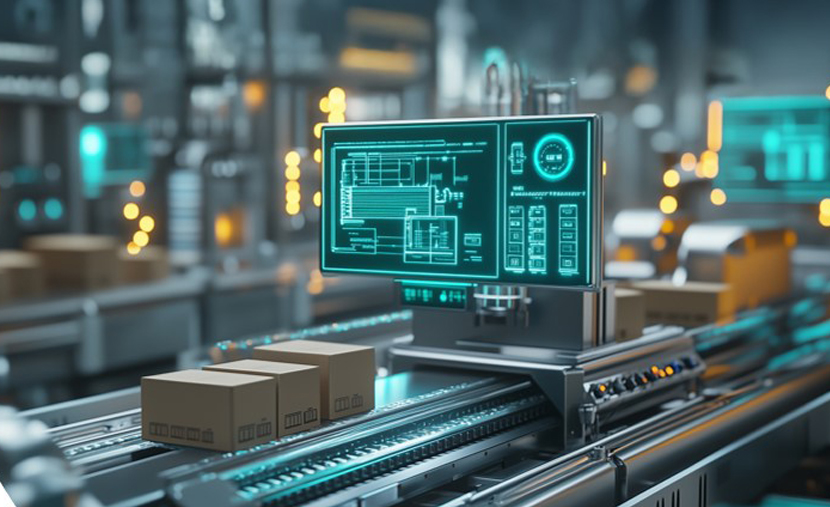

IoT Solutions

Transforming legacy manufacturing units into smart factories

Transforming legacy manufacturing units into smart factories

How does IoT work?

- The Industrial Internet of Things (IIoT) is a network of connected industrial devices that communicate and share data. This raw data is then processed to gain insights that enable rapid OEE improvement, reduce wastages, and improve competitiveness.

Insights gained from real time performance data can

The IoT Edge

Leverage the latest technologies to improve competitiveness and enhance market share & profitability simultaneously.

Improve Quality

- By visualizing impact of supply chain, equipment, and manpower issues .

Improve Equipment Efficiency

- RCA and remediation via real time insights.

Optimize Manpower

- By visualizing impQuickly identify internal SMEs to enable rapid L&D, reduce manpower. act of supply chain, equipment, and manpower issues .

Reduce Maintenance Costs

- Predictive / Autonomous, & Proactive maintenance.

Reduce Process Wastages

- RCA, and insights for cost reduction, and profitability.

The IoT Edge

Leverage the latest technologies to improve competitiveness and enhance market share & profitability simultaneously.

Improve Equipment Efficiency

- RCA and remediation via real time insights.

Optimize Manpower

-

By visualizing impQuickly identify internal SMEs to enable rapid L&D, reduce manpower. act of

supply chain, equipment, and manpower issues .

Reduce Maintenance Costs

- Predictive / Autonomous, & Proactive maintenance.

Reduce Process Wastages

- RCA, and insights for cost reduction, and profitability.

- Problems

- Solutions

- Benefits

Achieve productivity enhancement, improve quality consistency, and reduce wastages in existing facilities.

Large variety of equipment, some of which do not have any controllers / electronics.

Some manual labour dependent processes.

Large variety of products, SKU’s and technologies.

The following methodologies were implemented to overcome our internal challenges.

Innovative sensor-based approach to capture KPI’s on existing equipment without controllers.

Development of jigs with sensors to assist manual tasks and capture KPI’s.

Deployment of interactive HMI’s and integrating into existing ERP / MRP systems to capture task & quality data.

Since implementation, our IoT systems have been continuously utilized and improved, delivering phenomenal results.

OEE increased from 72% to 90%

Quality deviations reduced from 3.6% to 0.9%

Yield improved from 90.45% to 96.3%

9% reduction in manufacturing Costs.

ROI achieved in less than 45 Weeks.

USP Innomation’s IoT Solutions

Innomation’s domain expertise and unique approach to deploying IoT solutions in manufacturing are our USP.

Decades of experience in manufacturing equipment design and deployment provide deep insight into their capabilities.

Experience across multiple core manufacturing sectors including pharmaceutical, FMCG, chemical, defence, & aerospace.

Innomation’s IoT systems surpass competitors by overcoming data limitations in machine controllers and extraction constraints.

A top-down approach tailors solutions with sensing systems that collect manufacturing data, enabling IoT to enhance productivity, quality, and yield