Multi-Track Stick

Pack Machines

STP-600 | STP-900 | STP-1200

Multi-Track Stick Pack Machines

Innomation’s STP Series are vertical, intermittent-motion, fully servo-driven packaging machines that blend European engineering quality with Indian manufacturing agility. Built for industries where reliability, regulatory compliance, and cost-efficiency are paramount, these machines support a wide range of package formats and dosing systems.

The STP range is available in configurations tailored to Pharmaceutical, Nutraceutical, Food & Beverage, and Consumer Goods applications.

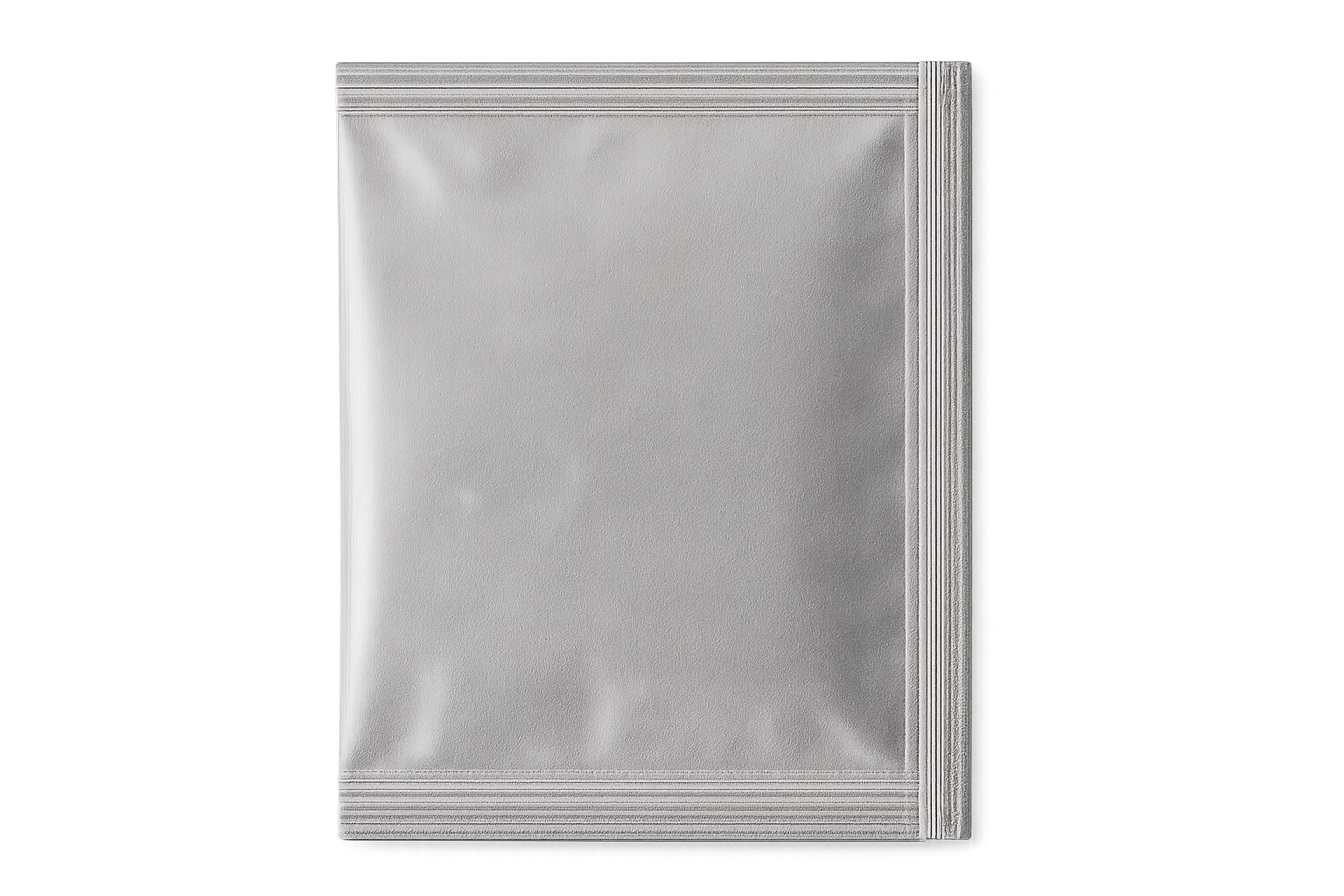

Types of Packages

Stick

Pack

3 Side Seal Stick Pack

Die-Cut Stick Pack

Versions

Pharmaceutical STP-P

- cGMP (USFDA)

- 21 CFR Part 11 (USFDA)

- CE

- ISO 14644-1 (Cleanroom)

- DQ/IQ/OQ/PQ Validation documentation

Nutraceutical STP-N

- cGMP(USFDA)

- 21 CFR Part 110/111 (USFDA)

- ISO 22000 / HACCP

- IQ/OQ validation Documentation

Food & Beverages STP-F

- FSSAI

- HACCP

- SO 22000 / FSSC 22000

Dosing Systems

Powders

Our in-house designed and precision-machined auger filler features a temperature-controlled casing, ensuring jam-free, high-accuracy filling—even with challenging powders like cocoa, milk powder, powdered sugar, and ground spices.

Granules

Our Basiculating dosing

systems deliver high filling accuracy while handling irregular granules with varying bulk densities. Designed for easy cleaning and fast changeovers, they ensure efficient operation with minimal downtime.

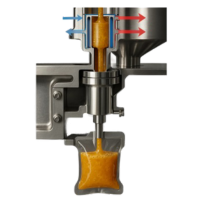

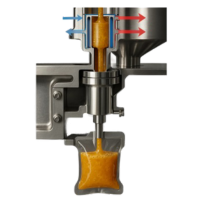

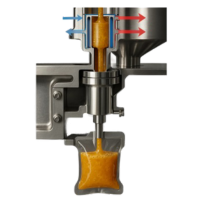

Liquids & Pastes

Innomation offers both piston and ultrasonic fillers for a wide range of liquids and pastes. Temperature-controlled filling ensures consistent weight accuracy and jam-free operation.

Discrete Products

Tablets, capsules, candies, and other discrete products can be efficiently counted and dispensed from bulk into individual stick packs. Integrated visual inspection and rejection systems ensure that only quality-verified products reach your customers.

Dosing Systems – Powders & Granules

Powders

Our in-house designed and precision-machined auger filler features a temperature-controlled casing, ensuring jam-free, high-accuracy filling—even with challenging powders like cocoa, milk powder, powdered sugar, and ground spices.

Granules

Our Basculation dosing systems offer outstanding filling accuracy, even with irregular granules of varying bulk densities. They are crafted for easy cleaning and quick changeovers, ensuring seamless operation with minimal downtime.

Liquids & Pastes

Our Basiculating dosing systems deliver high filling accuracy while handling irregular granules with varying bulk densities. Designed for easy cleaning and fast changeovers, they ensure efficient operation with minimal downtime.

Discrete Products

Tablets, capsules, candies, and other discrete products can be efficiently counted and dispensed from bulk into individual stick packs. Integrated visual inspection and rejection systems ensure that only quality-verified products reach your customers.

Dosing Systems – Powders & Granules

Powders

Our in-house designed and precision-machined auger filler features a temperature-controlled casing, ensuring jam-free, high-accuracy filling—even with challenging powders like cocoa, milk powder, powdered sugar, and ground spices.

Granules

Our Basculation dosing systems offer outstanding filling accuracy, even with irregular granules of varying bulk densities. They are crafted for easy cleaning and quick changeovers, ensuring seamless operation with minimal downtime.

Liquids & Pastes

Our Basiculating dosing systems deliver high filling accuracy while handling irregular granules with varying bulk densities. Designed for easy cleaning and fast changeovers, they ensure efficient operation with minimal downtime.

Discrete Products

Tablets, capsules, candies, and other discrete products can be efficiently counted and dispensed from bulk into individual stick packs. Integrated visual inspection and rejection systems ensure that only quality-verified products reach your customers.

Dosing Systems – Powders & Granules

Powders

Our in-house designed and precision-machined auger filler features a temperature-controlled casing, ensuring jam-free, high-accuracy filling—even with challenging powders like cocoa, milk powder, powdered sugar, and ground spices.

Granules

Our Basculation dosing systems offer outstanding filling accuracy, even with irregular granules of varying bulk densities. They are crafted for easy cleaning and quick changeovers, ensuring seamless operation with minimal downtime.

Liquids & Pastes

Our Basiculating dosing systems deliver high filling accuracy while handling irregular granules with varying bulk densities. Designed for easy cleaning and fast changeovers, they ensure efficient operation with minimal downtime.

Discrete Products

Tablets, capsules, candies, and other discrete products can be efficiently counted and dispensed from bulk into individual stick packs. Integrated visual inspection and rejection systems ensure that only quality-verified products reach your customers.

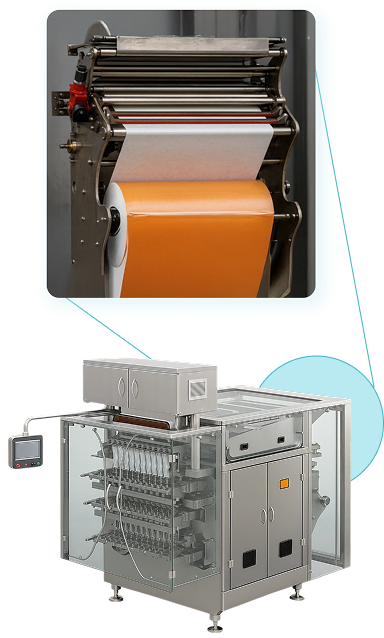

Key Features - Web handling

Feature:

Continuous Unwinder

Benefit:

Enables jerk-free film unwinding, helping reduce laminate costs while improving machine throughput.

Feature:

Servo Controlled Web Guiding

Benefit:

Offers up to 100 mm of correction, ensuring precise laminate centering even with telescoped or loosely wound rolls.

Feature:

Ergonomically designed splicing table with automatic clamping, eye mark-controlled guided cutting, and built-in tape dispensing

Benefit:

Significantly reduces splicing time, errors, and material wastage.

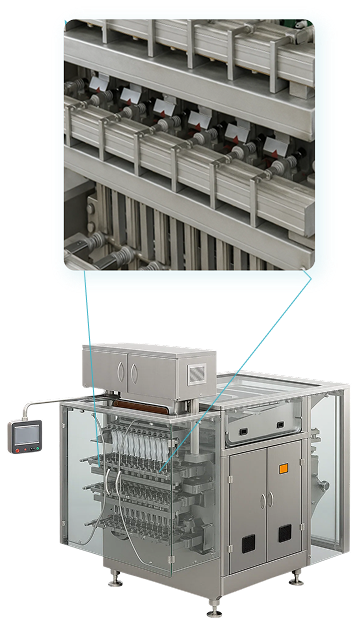

Key Features - Sealing

Feature:

Fully Servo Controlled Sealing

Benefit:

Enables independent electronic adjustment of sealing time, temperature, and pressure for optimal performance.

Feature:

PVD Coated Sealing Jaws

Benefit:

Enhances heat transfer and surface temperature uniformity while reducing stickiness and material buildup

Feature:

Sealing jaws with cascading, independently controlled heaters and sensors

Benefit:

Extend cartridge heater life and provide redundancy in temperature monitoring—reducing maintenance costs while enhancing machine uptime and sealing reliability.

Key Features - Performance & Compliance

Feature:

Fully enclosed transparent impact resistant guarding

Benefit:

Provides complete visibility while ensuring safety. All guards are secured with electronic safety latches integrated with a safety PLC

Feature:

Machined Collars

Benefit:

Machined, retractable collars enable quick and reliable changeovers increasing machine availability

Feature:

Designed for Performance

Benefit:

Our machines achieve throughputs of up to 90 cpm—significantly higher than the industry standard of 50–60 cpm.

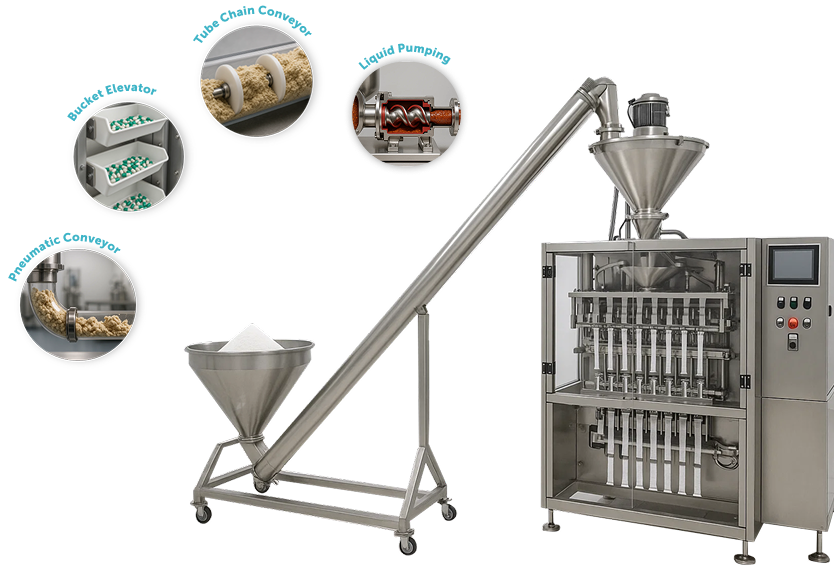

Pre Feeding Units

Innomation offers a comprehensive range of pre-feeding units designed to extend the intervals between manual product loading and to serve as buffers between upstream processing and downstream packaging operations. Our solutions include:

Ready to optimize your

stick pack production?

Ready to optimize your stick pack production?