Precision Manufacturing Capabilities

Innomation maintains state-of-the-art manufacturing facilities incorporating the latest CNC machines, top-of-the-line TIG & MIG welding stations, and a comprehensive range of quality control instruments all backed by a centralized production, planning & control software. It is here that we manufacture thousands of complex, high-value components every year to strict regulatory, quality, and customer-specific requirements.

Our manufacturing facility is backed by a dedicated design and development office specializing in jigs & fixtures, tooling, mechanization & automation, and work-holding design, helping us achieve very high productivity and consistency in quality. Ultimately this results in a better value proposition for our customers.

Why choose us

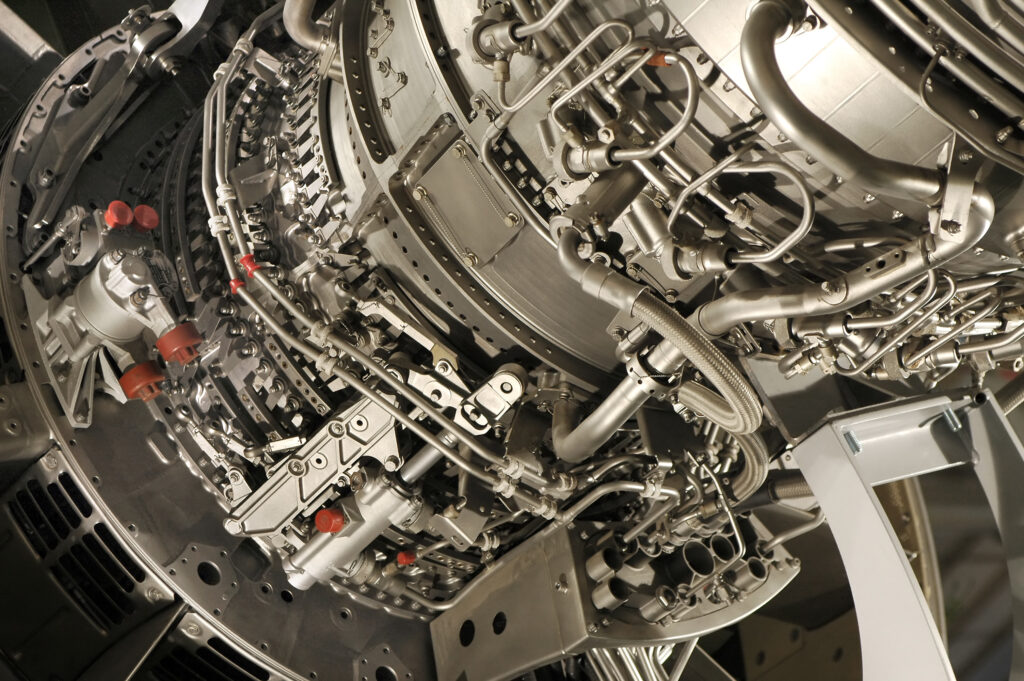

- Experience: Team Innomation offers our customers the expertise and know-how that comes with nearly 2 decades of manufacturing for various sectors including Defence, Aerospace, FMCG, Tobacco, and Telecom.

- Turn-key Facility: Whether it is raw material cutting, edge preparation, welding, turning, milling, EDM, or surface finishing, we offer our customers a comprehensive range of metal and polymer manufacturing facilities.

- Quality Assurance: With an in-house, fully equipped quality control lab driven by continuous in-process inspections, you can be rest assured that every component meets the required specifications.

- Quick Lead Times & Value for Money: With the help of the latest technologies, in-house jigs & fixture design capabilities, highly skilled and driven workforce, Innomation is able to set new benchmarks in productivity, ensuring that we are able to offer the best possible prices and lead times to our customers.

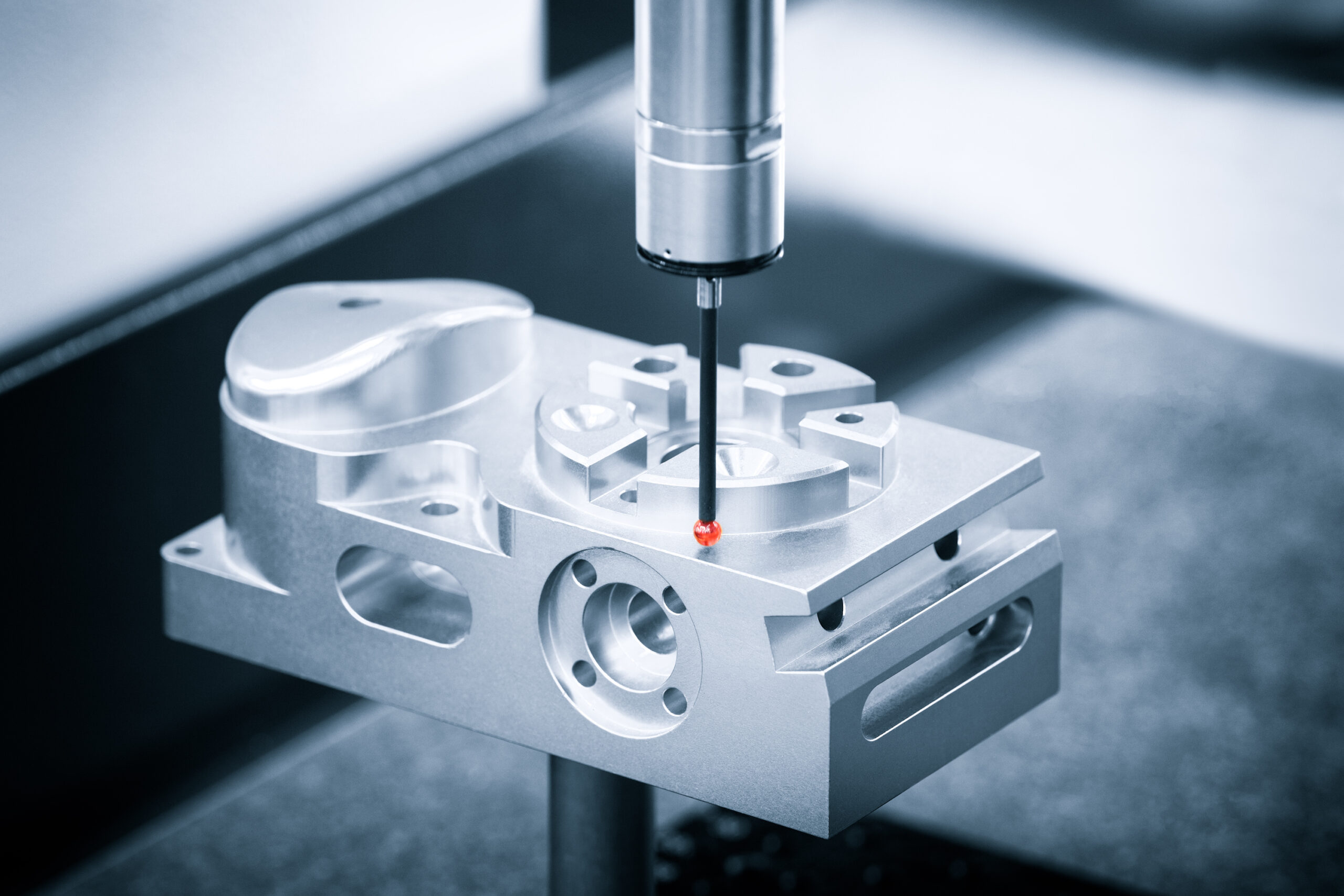

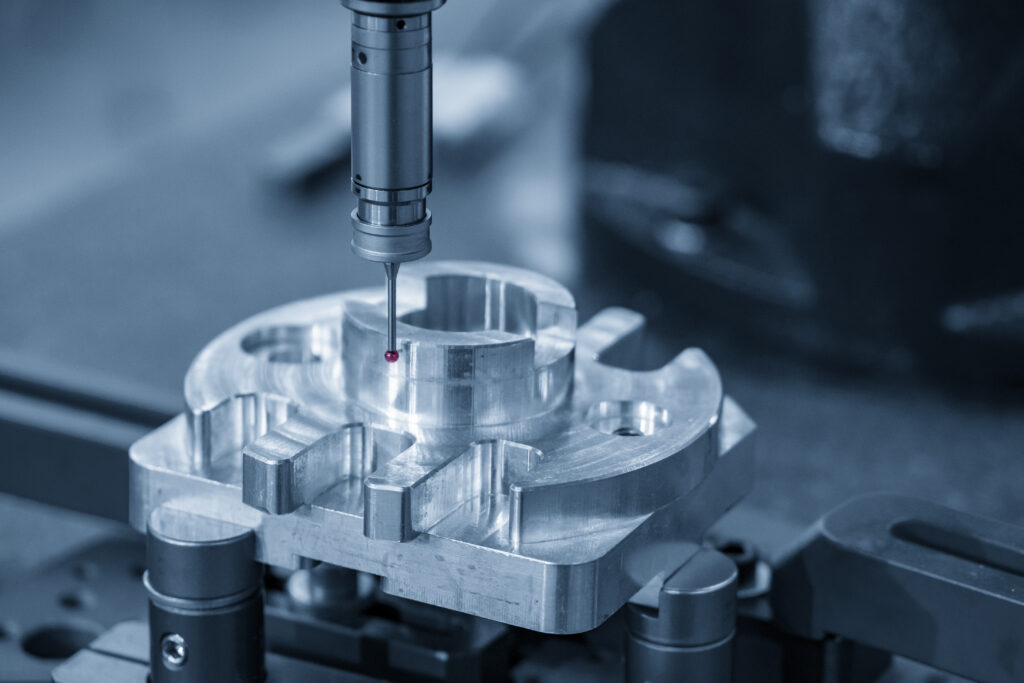

CNC Machining

Our in-house precision manufacturing facilities are equipped with state-of-the-art CNC machines, tools, and consumables and regularly handle complex geometries in touch with machine materials. In addition to machining components required for our own high-performance automation equipment, Innomation also provides precision manufacturing services for a wide range of industries including Defence, Aerospace, Pharma, and FMCG.

With heavy investments in technology, infrastructure, talent acquisition, and skill development, our CNC machining capabilities are continuously upgraded to meet and exceed global standards of precision, productivity, and viability.

Material Handling Capabilities

- Stainless Steels: 15-5, 17-4, 17-7, A-286, AISI 200, 300, & 400 series.

- Titanium & Titanium Alloys: Ti 6-4 Grade 1 to 4, Grade 9, 5-2.5, 6-2-4-2, 6-4, 6-6-2

- Aluminium & Aluminium Alloys: 7075, 6061, 6063, 2024, 5052, 4032, 4047

- Inconel Alloys: Inconel 188, 625, 718, 750, 230

- Steel Alloys: EN 8, 9, 15, 19, 36A, 47J, 353, D2, D3, H21, H23, O1, A2

Standard Tolerances for CNC Machined Parts

With continuous improvement in technology and up-skilling of our workforce, Innomation is regularly able to achieve tolerances as tight as 10 microns in hardened metals and below 50 microns in polymers.

Fabrication

From raw material UT testing and inspection to CNC cutting, edge preparation, TIG/MIG welding, drilling & tapping, up to finishing and finished goods inspection, our fabrication facility is equipped with the latest technologies, SOPs, and a highly skilled and driven workforce. Whether it is a prototyping need or a mass production requirement, we at Innomation have the capability and will to exceed your expectations!

Welding

Innomation has state-of-the-art TIG/MIG welding equipment coupled with trained and certified welders experienced in delivering high-quality welding jobs while reducing lead times and production expenses. From producing a single prototype to delivering a high-volume order, our expert teams are trained to identify and execute precision welding services that efficiently meet the design and regulatory requirements.

We approach every project with a sense of urgency and attention to detail. We’re capable of providing both MIG and TIG welding services. As a single-source production welding service, we aim at being able to assist in every stage of the project from design and engineering through finishing.

Quality

At Innomation, we have implemented the most rigorous manufacturing processes & quality control procedures, coupled with a state-of-the-art ERP system to ensure that we exceed global benchmarks of manufacturing productivity & quality.

Our continuous commitment and rigorous regimen in our daily activities ensure zero rejection rate and the consistent-timely delivery of quality products. Our quality control facilities include

- Temperature, humidity & dust controlled, isolated QC lab.

- Mitutoyo 2D CMM- o.1 micron resolution and 0.5-micron repeatability.

- Assortment of slip, plug, ring & thread gauges up to IT5 grade.

- Class 0 surface table as per IS 7327-2003

- Complete range of Mitutoyo Verniers, Micrometers & Bore Gauges.

- Automated calibration tracking & re-calibration scheduling for all tools.

- Integrated QR code serialized labeling of all components with linked permanent inspection records.

- Non-conformance procedures integrated into the ERP system as per ISO 9001:2015

Assembly & Integration

Innomation maintains a specialized, end-to-end assembly facility with several industry-specific purpose-built work areas. This includes a dedicated controlled working environment for the assembly and quality management of sensitive modules. We provide end-to-end assembly services from initial part assembly and inspection to complex packaging, comprehensive quality checking, and delivery straight to the door of our customers.

Storage & Traceability

At Innomation, we have implemented state-of-the-art QR code-based storage and traceability solutions fully integrated into our ERP system. All raw materials, bought-outs, & components are traced continuously with the help of labels printed with a unique QR code.

Some of our traceability capabilities include:

- Fully enclosed, restricted access storage & racking system with a capacity of 60 metric Tons.

- Fully labeled racks, shelves, and bins with integrated unique QR codes.

- UV Stabilized specialized long-life labels with adhesive backing for all components.

- QR code integrated with job cards, route cards, inspection reports, and automated time tracking for end-to-end traceability of components during and post-manufacturing.

- Inventory management system capable of tracking from material requisition through manufacturing up to dispatch.

- Quarterly physical audits and inventory non-conformance reports and CAPA integrated into ERP.

Polymer Processing

With the top of the line Kennametal, Taegutec, and Kyocera tools & inserts coupled with Blaser lubricants, our facilities are capable of handling a vast variety of ferrous, and nonferrous metals and specialty polymers with ease.

We have experience with handling and processing of the following polymers:

- Polyetherketone

- Thermosetting Polyamide

- Polyamide-imide

- PTFE & PCTFE

- DuPont Vespel & other Polyamides

- Polysulfone

- Noryl PPO